Transit Testing

Transit testing refers to lab tests that simulate the movement of a package throughout the supply chain. These tests consist of multiple drops, compression, atmospheric changes, and vibrations. The International Safe Transit Association (ISTA) has certified test protocols that are catered to specific types of supply chain movements. Walmart utilizes these tests to ensure that products arrive to customers in perfect condition.

Purpose

Transit testing helps reduce damage by ensuring the product's packaging can withstand the rigors of delivery to the customer. Walmart.com may require that specific products pass an ISTA transit test in the packaging that goes out to the customer.

Scope

Transit testing is required for both Domestic and Direct Import items that are Walmart.com only (items not shared with stores). You can review the requirements and exceptions below.

Items that Require Testing

- Private Brands (see exempt product types below)

- Hard Goods (e.g., electronics, furniture, sporting equipment, appliances, bicycles, strollers, and car seats)

- Glass or “breakable” items (non-consumables)

Items Exempt from Testing

- Soft Goods (e.g., mattresses, cushions, apparel, linens, towels, pillows, backpacks, soccer balls)

- Small Consumables (e.g., food, grocery, makeup, office supplies, baby consumables)

Process

You will receive an email from the Product Development team if your products require testing. Upon notification, submit a production sample of the item to an ISTA-certified lab for testing. If you or the manufacturer of the item makes any changes to the item packaging after this initial testing, you will need to send another sample for retesting.

Like items (e.g., the same item in a different color) can be waived from transit testing upon approval from the Product Development or the Returns Management teams. For more information, please see the Transit Testing Waiver section below.

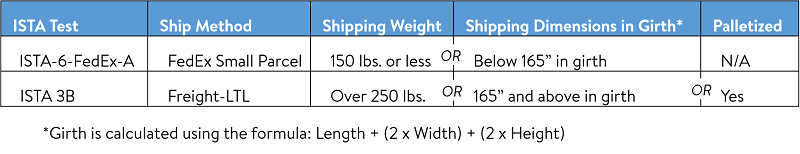

We require one of the following tests, based upon the weight and dimensions of the item. If you are unsure which test protocol your item(s) require, contact the Returns Management team.

Once the transit test results are complete, the testing facility should send you a copy of the results. You, or your Global Sourcing Partner, must provide a copy to Returns Management.

Transit Testing Waiver

Walmart.com will review transit test waivers and approve or deny exceptions for "like-items" you've carried in the past based on their current waiver requirements. To apply for a waiver, email the Returns Management team with a list of the UPCs of the new and like-items.

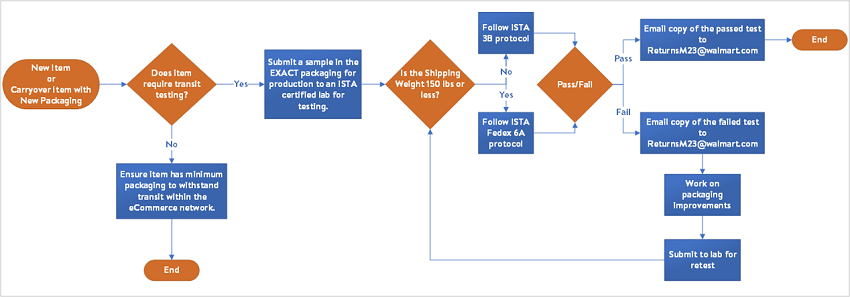

Process Flow

This flowchart outlines the process flow for transit testing.

Transit Testing Lab Options

The sections below provide detailed information on transit testing facilities and how to contact them to set up tests for required items.

Walmart.com Transit Testing – International Lab Options

Transit testing can be conducted by any independent 3rd party ISTA-certified lab that uses the appropriate testing protocol and procedures. You are responsible for the cost of samples, shipping, and test fees for all tests.

Walmart has negotiated reduced rates with the following labs that have multiple locations internationally. When you submit a request form, indicate that this test is for Walmart.com to ensure that you are eligible for these rates.

Bureau Veritas

- Email a completed Account Request form to WalmartTestingMail@us.bureauveritas.com to create an account

- Once you create an account, you can request transit tests using https://www.bvonesource.com/wps/portal

- Locations in Shanghai, Shenzhen, and Hong Kong

SGS

- Contact one of the following individuals for instructions and lab locations:

- Heather Maxwell, Global Key Account Manager

- Office: 479-273-3090

- Mobile: 479-268-0262

- Email: Heather.Maxwell@sgs.com

- Allison Giezentanner, Key Account Manager

- Office: 479-273-3786

- Mobile: 479-295-2979

- Email: Mary.Giezentanner@sgs.com

Intertek

Contact the lab directly to request transit testing.

- China – Cherry Sun Cherry.Sun@intertek.com

- Hong Kong – Kennix Yeung – Kennix.Yeung@intertek.com

Footprint

Contact the lab directly to request transit testing.

- Address – Unit 10D, 168 PingWu Road, YuJia Plaza, Changning District, Shanghai China

- Contact – Eugene Chua, Telephone +861 376 120 8875

Walmart.com Transit Testing – Domestic (U.S.) Lab Options

Like international transit testing, domestic tests can be conducted by any independent 3rd party ISTA-certified lab that uses the appropriate testing protocol and procedures. You are responsible for the cost of samples, shipping, and test fees for all tests.

Walmart has negotiated reduced rates with the following labs that have locations across the United States. When you submit a request form, indicate that this test is for Walmart.com to ensure that you are eligible for these rates.

FedEx Packaging Lab

The FedEx packaging lab is located in Collierville, TN.

- Email the completed Domestic Transit Testing form to packagingservices@fedex.com.

- Enter Walmart.com in the section “Is this test part of a vendor approval program?”

- Complimentary testing for all FedEx business account holders up to 4 packages per cycle.

- Each cycle is 4-6 business days for small parcel and 5-7 business days for LTL (freight)

- Complimentary testing is for FedEx 6A, 6B, and 3B protocols only. Other protocols are available at additional costs.

Bureau Veritas

The Bureau Veritas packaging lab is located in Buffalo, NY.

- Email the completed Transit Testing Account Request form to WalmartTestingMail@us.bureauveritas.com to create an account.

- Once you create an account, you can request transit tests here.

Footprint

The Footprint packaging lab is located in Gilbert, AZ.

- Email the completed Domestic Transit Testing form to orders@footprintus.com

SGS

The SGS packaging labs are located in Fairfield, NJ, and Appleton, WI.

- Contact an Account Manager to help provide instructions and point you to the appropriate lab locations:

- Heather Maxwell, Global Key Account Manager

- Office: (479) 273-3090

- Mobile: (479) 268-0262

- Email: Heather.Maxwell@sgs.com

- Allison Giezentanner, Key Account Manager

- Office: (479) 273-3786

- Mobile: (479) 295-2979

- Email: Mary.Giezentanner@sgs.com

- Heather Maxwell, Global Key Account Manager

Intertek

Contact the lab directly to request transit testing. The Intertek packaging lab is located in Grand Rapids, MI.

- USA – Jennifer Jenkins – jennifer.jenkins@intertek.com

Minimum Packaging Guidelines

The following guidelines will help set you up for success when you are packaging your products for shipment and passing the required ISTA transit tests.

Walmart packaging guidelines can be found in Supplier Academy:

Expectations for Corrugated Boxes

All products shipped to a Walmart.com Fulfillment Center must arrive in a warehouse pack carton (master carton) capable of withstanding the rigors of inbound transportation and conveyance as an individual unit.

Best Practices

- Product should be placed in the center of the box with cushioning on all 6 sides.

- Cartons must have an equal product weight distribution and surfaces must be flat and strong enough to support the package weight without distortion, deflection, or bending.

- Both single-wall and double-wall corrugated containers are acceptable if the minimum strength requirements are met. (Reference: Retail Link > Learn > Dotcom > Fulfilling Orders > Walmart.com Packaging and Labeling Documents > Walmart.com Packaging and Labeling Manual)

- Recycled corrugated material is acceptable.

- If a recycled corrugated board is used, the box needs to meet a higher strength requirement to match the performance provided by new materials.

- A Bursting Test Strength appropriate for the product weight with a minimum rating of 200 lbs. per square inch is strongly recommended.

- Corrugated packaging must have enough strength to support stacked pallet loads up to a five-foot stack height in the warehouse.

- Cartons must be sealed with a 3” Poly tape formulated for the corrugated board you are using.

- If using recycled corrugated board, use tape formulated for high recycled content.

- If using thermal labels, please ensure they are placed on the corrugated box and not on the tape.

- Cartons may be shrink-wrapped if the mil is thick enough to hold up to normal Distribution Center (DC) processing (80-gauge, 15-inch).

- Labels must be placed directly on the corrugated box and not on the shrink-wrap.

Avoid

- Reused corrugated material is not accepted.

- Do not display the vendor name on the tape is not recommended to avoid theft.

- Exterior strapping of any kind should be avoided. This is often used as a handle and causes tearing of the corrugate.

- Cartons shall not include handles or openings. If your buyer approves this packaging, the opening must be strong enough to be used as a handle or clearly marked with a “Do Not Use As Handle” sticker.

- Do not ship product in an open-faced or display box.

Additional Packaging Standards

- In the event of product designated as ship-alone or ship-as-is, the warehouse pack carton must be capable of serving as the outbound carton when shipped to the customer.

- Ship-as-is: A selling unit that exceeds 30”x26”x30” on any dimension

- It must be able to ship-as-is in its packaging and will not be over-boxed by Walmart.com prior to shipment to the customer.

- Items that stack inside each other for shipment, like plastic bins and garbage cans, are acceptable without ship-as-is packaging.

- Arrows indicating stacking and handling directions and applicable handling warnings such as Team Lift must be printed on the carton.

- If the product is packed in multiple cartons, each carton must indicate “Carton 1 of 2”, “Carton 2 of 2”, etc.

- Some items, such as glass top tables, need special protection – foam or extra corrugated sheets must be added to prevent any damage of fragile items.

- Polyethylene foam sheeting (minimum 1/16” thickness) shall be used as a scuff protection to blanket the individual components and protect finishes. Packages still need additional cushioning to prevent damage.

- Apply edge protectors to the carton to avoid heavy abrasion.

- Polybags can be used for rugs, mattresses, and cushions. All polybags need to be heavy duty (6 mil thick). Thermal labels should be applied to a landing pad on the polybag or utilize FedEx Tie-on-Tags.

- Supplier pack carton dimensions & weight, as well as shipping dimensions & weight, of the sell-unit must be submitted to your buyer prior to initial shipment to a Walmart.com Fulfillment Center.

DSV Packaging Standards

- DSV must ship in plain, unbranded boxes.