Distribution Warehouse Capacity

Distribution warehouse capacity is the number of units a distribution warehouse can ship in a given day for Walmart.com orders. Suppliers must accurately set capacity to ensure on-time shipping and on-time delivery. Walmart uses your distribution warehouse capacity to manage order flow and ensure customer-promised delivery dates are met. When capacity fills to the daily capacity limit, orders (units) will move to the following day.

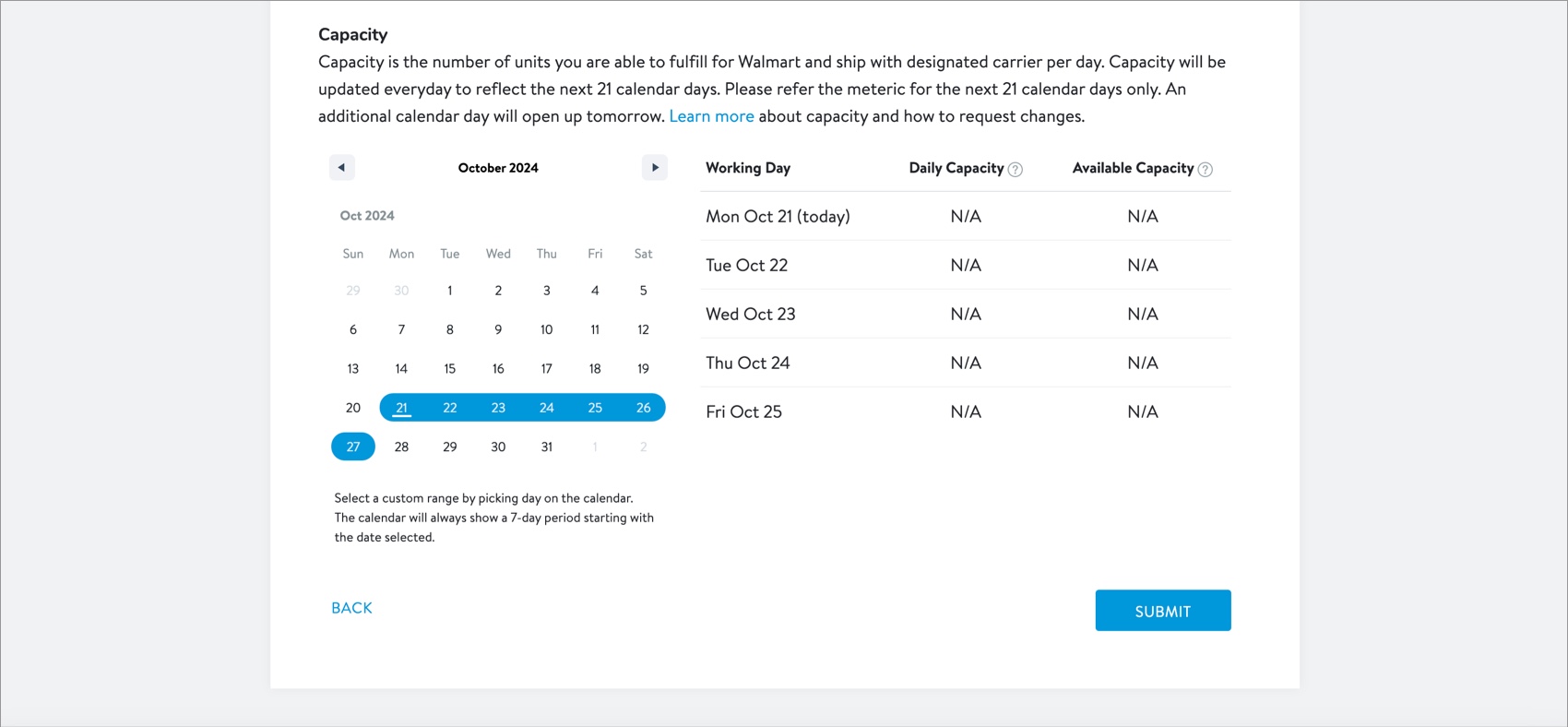

You can view the capacity for your warehouses from within Supplier One. Click Account at the top right corner of your window and select Supplier profile. Then, select Shipping and warehouses and expand Warehouse Information. Select the warehouse you wish to view by clicking on it and scrolling to the Capacity section.

Set Capacity

Capacity per distribution warehouse is set in an internal Walmart system. Walmart will work with the supplier to ensure an accurate capacity is set for each distribution warehouse. Daily capacity is set for all working days, in units, for each distribution warehouse.

Because capacity is set in an internal Walmart system, it is important that you work with Partner Support to ensure your capacity is correct. If you have questions about your capacity or need support, please submit a ticket to Partner Support by clicking Help > Manage tickets in Supplier One. If you want to update your Distribution Warehouse capacity, please submit a completed DSV Capacity Template when you create your case.

How Capacity Affects Suppliers

Inaccurate capacity may result in lost sales or late shipments. If the capacity is set too low, that warehouse may not receive the number of orders they are capable of fulfilling, resulting in lost sales. If the capacity is set too high, that warehouse may not be able to process and ship all orders received by the expected ship date (ESD), which may result in chargebacks.

Each order you receive from Walmart is assigned an expected ship date. This is the date the order is expected to ship from your warehouse (picked up by the carrier on this date). Orders must be shipped by the expected ship date to prevent late shipment and chargebacks. For more details, please review Operational Expectations - On Time Shipping.

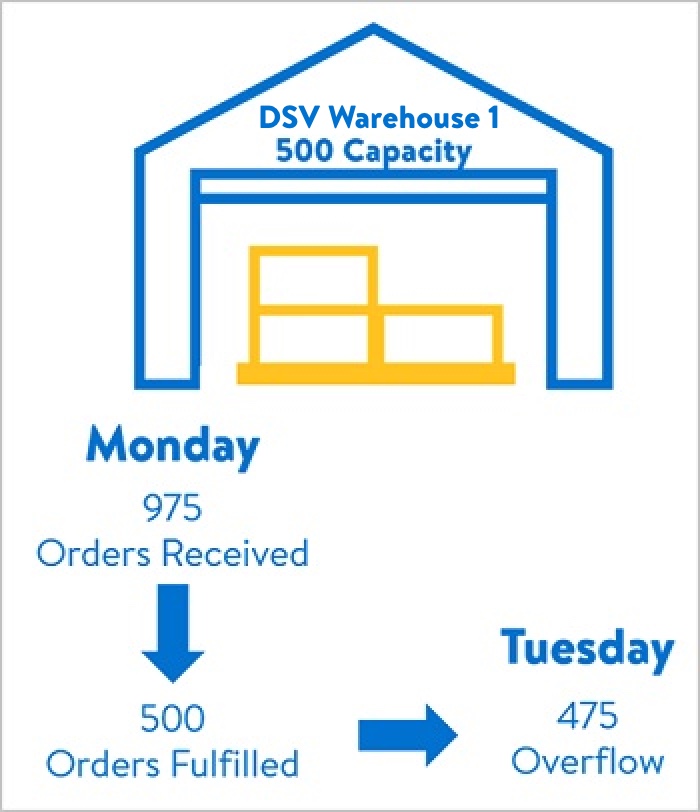

Capacity Example

Capacity ensures the number of orders (units) sent to a distribution warehouse each day does not exceed the capacity set for that day. When number of units reach the capacity set for that day, the overage will then be assigned into future dates.

For example:

DSV Warehouse 1 has a capacity of 500. On Monday, 975 orders are placed on Walmart.com for that warehouse. Walmart assigns 500 units to be fulfilled on Monday, with the remaining 475 units to be processed on Tuesday. Warehouses should ship all overflow orders before processing and shipping any units received on Tuesday.