DSV Performance Best Practices

Walmart’s mission is to provide you with the tools you need to improve your performance and succeed as a DSV. This article provides suggestions and best practices for improving your order defect rate, which will improve your DSV scorecard. For more details on the scorecard, review DSV Program and Performance Standards.

Please ensure that your distributor settings are set correctly in Supplier One. To verify these settings, please review Add or Update DSV Distribution Warehouses.

Reduce Shipping Defects

Shipping defects occur when orders picked up by the carrier late or shipped after the expected ship date (ESD). Each PO is assigned an ESD that the order must ship by to meet the delivery date that was communicated to the customer.

The following practices will help you improve on-time shipping:

- Ensure that all orders are shipped, picked up, and scanned by the carrier by the expected ship date (ESD).

- Work with local carrier hubs to verify that your orders are picked up and scanned the same day. You are expected to manage relationships with the carrier hubs in your area.

- Lead (lag) times are only granted for custom made, built to order, or large freight items. If your items fall in any of these categories, click Help > Manage tickets within Supplier One to open a case for Partner Support (select Orders and Shipping > Others for the issue) to request lead time. You can review Fulfillment Lead Time for additional details and requirements.

- The default daily order cut-off is 12 PM local warehouse time. The cut-off time to be eligible for the 2-day program is 12 PM local time.

- Check your order dashboard 30 minutes to 1 hour after the order cut-off time to ensure that all orders with same day ESD are processed.

- If you fall behind in shipping, consider setting an operational outage in Supplier One to give you time to catch up. Please note setting an operational outage pushes out the ESD for future orders, it does not stop orders from coming in. Any orders received before the outage is set will have with the original ESD.

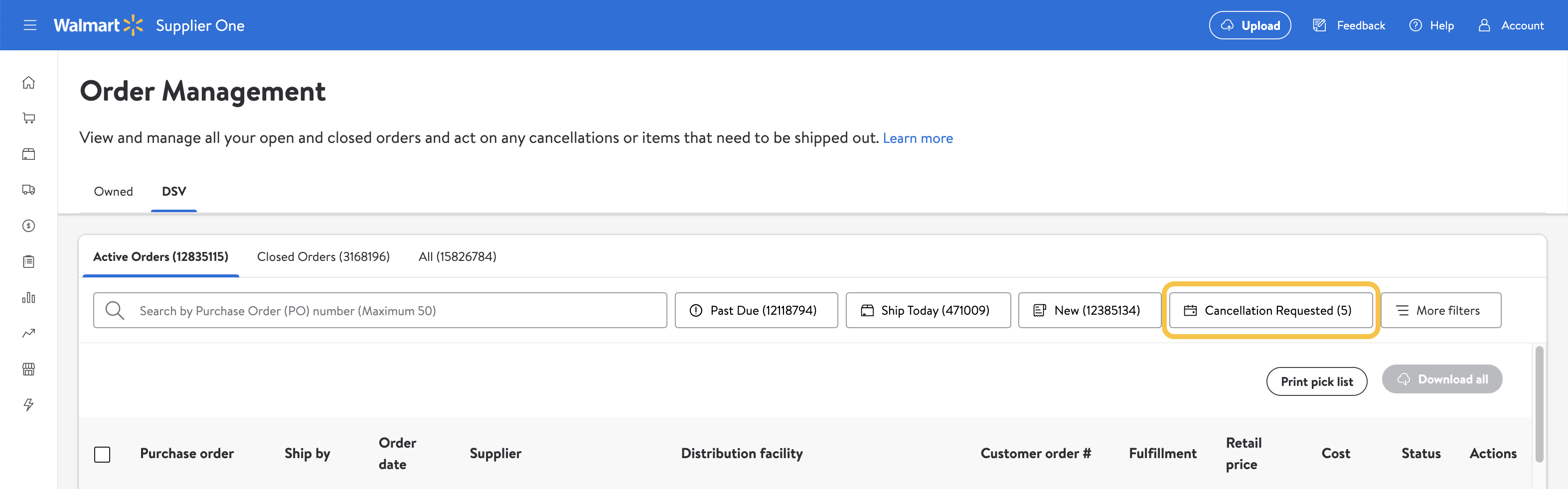

- Closely monitor your Order Management dashboard in Supplier One daily to make certain that your orders are shipped for the current day.

To learn more about on time shipping and how it is measured, please review Operational Expectations - On Time Shipping.

DSV 2-day Program

DSV 2-day Minimum Eligibility

- DSV 2-day logic is enabled at supplier distributor location level on a weekly basis and is available to all DSVs that meet the 2-day requirements below.

- Locations that meet these requirements will be enabled automatically. Locations that fall below these requirements will be disabled until they meet the requirements again to protect the customer experience.

2-day Requirements

- 2-week trend of 90% or above On-Time-Delivery (OTD)

- 12 PM or earlier cut-off time

- Zero (0) Day Lag / Lead Time

- Zero (0) Capacity Days Full

Important Note - Walmart Carrier Escalation Guidelines

If your shipment is late due to carrier capacity (pick-up volume) you must:

- Speak with your local carrier representative and find out what volume they can commit to picking up on a daily basis. It is your responsibility to manage the carrier relationship. For more details about Walmart's carrier guidelines, please review the Carrier Relationship Guidelines.

- If your order backlog is less than 1,000 orders, reduce your Warehouse Capacity to the volume your carrier can commit to picking up. Failure to decrease your capacity to reduce your late shipments will result in late shipment chargebacks and/or account suspension.

- If your order backlog is more than 1,000 orders, reduce your Warehouse Capacity AND submit a Carrier Escalation case with Partner Support by clicking Help > Manage tickets within Supplier One and selecting Orders and Shipping > Others.

Reduce Rejection Defects

Rejection defects are caused by backorders, discontinued POs, or sending a cancellation without a request to cancel from Walmart. Accurate inventory counts will help to avoid out of stock or backorder rejections. To ensure that your inventory is up to date, send at least one inventory feed a day. We encourage our DSV Partners with a high volume of orders to send multiple feeds a day to maintain accurate inventory counts.

The following practices will help you reduce order rejections:

- Update inventory to 0 immediately after your item is out of stock to avoid receiving additional orders. Do not hold on to POs if you do not have available inventory.

- Update on hand availability to 0 before you remove an item from your inventory feed for any out of stock items.

- Only use Distributor Cancel in Supplier One when there is a request to cancel from Walmart. You can find all request to cancel POs from Walmart by clicking DSV Active Orders in Order Management in Supplier One.

- For any issues with an item SKU, cost discrepancies, or address issues set the PO status to Unrecognized and click Help > Manage tickets within Supplier One to create a case with Partner Support to report the issue. Select the option that best describes your issue (e.g., Orders and Shipping > Others).

EDI vendors should review all EDI status codes to verify that they are mapped correctly. EDI Status Codes are:

- IA - Acknowledge

- R4 - Backorder

- R1 - Discontinue

- R2 - Unrecognize

- ID - Cancellations

- AR - Wave

For more details about these codes, please visit the Developer Portal.

Reduce Return Defects

Return Defects apply to orders that have been returned due to problems with the product delivered to the customer.The following practices will help you reduce customer returns:

- Ensure that the pictures attached to your listing are high-quality images of the item (taken in a studio) as opposed to computer-generated images.

- Internal product protection should be durable enough to support shipping individual items to customers without becoming damaged in the process. If an item is fragile, there should be more packaging and/or protection.

- Perform frequent quality assessments for items that require assembly. Verify that all necessary parts are in the box and test that the products assemble correctly.

- Make sure that the color swatches match the item color and that naming conventions are clear to all customers.

- When you place labels on outgoing packages, they need to be clearly visible and properly adhered to the box to ensure that labels do not fall off during transit.

To learn more about customer returns and to view best practices, please view our Returns Reduction Guide.